Date: 1st September 2021

Man-made high-performance polymers are in the main non-biodegradable and derived through energy intensive processes driven by fossil fuels and involving toxic solvents and byproducts. Synthetic biology holds the promise of providing biodegradable, renewable, low-energy and aqueous-based solutions and engineered microbes have been successfully used for scalable production of many small-molecule compounds. However, this approach for the synthesis of high-performance polymeric materials remains a major challenge. Now, researchers have engineered microbial production of muscle titin polymers yielding high-performance fibres which outperform many synthetic and natural polymers.

Many high-performance natural materials are protein-based and derive their superior mechanical performance from hierarchical assemblies of ultra-high molecular weight (UHMW) proteins with highly repetitive amino acid sequences. However, the repetitive nature of these proteins make it exceedingly difficult to produce in microbes due to genetic instability, low translation efficiency, and the associate high metabolic burden it places.

One protein of great interest, which makes for an excellent candidate for environmentally friendly applications such as a wide-range of biomedical applications and even commercial textiles, is the muscle protein titin. However, its desirable mechanical properties such as passive strength, damping capacity, and rapid mechanical recovery is derived from its UHMW and highly repetitive sequences of hundreds of folded immunoglobin (Ig) domains. Whilst many attempts to engineering titin-like materials have been attempted only relatively short fragments to date have been achieved.

Now, researchers at Washington University in St. Louis, US, led by Fuzhong Zhang have developed a synthetic chemistry approach to polymerise proteins inside of engineered microbes, enabling the production of high molecular weight muscle protein, titin, which when spun into fibres were stronger than Kevlar.

To start the team employed a synthetic biology approach to mitigate the challenges of genetic instability and low translational efficiency in Escherichia coli. They genetical fused both terminals of a relatively short titin subunit (4x Ig domains) with fast-reacting split-inteins (SI), which catalysed in vivo protein polymerisation, in effect producing UHMW titin polymers through multiple round of intracellular SI-catalysed ligations of the subunits. Cells expressing the chimeric protein yielded a cluster of UHMW products up to and above 460 kDa whilst cells expressing the 4xIg monomer produced proteins at the expected molecular weight of 43kDA.

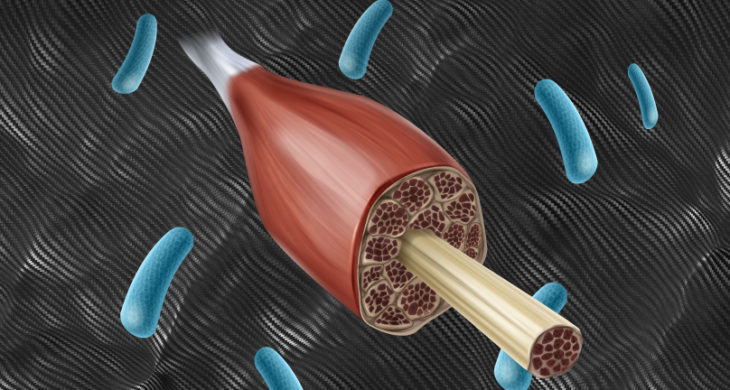

Next, the team had to process the polymers into usable fibres for practical applications. Here, they used wet-spinning of the UHMW synthetic titin to yield monofilament fibres.

The resulting fibres had high strength, modulus, extensibility and toughness which far exceeded values measured for muscle fibres and individual myofibrils. Furthermore, the toughness measures exceeded those of many of the toughest synthetic and natural materials, and far exceed those of traditional microbial materials.

Within muscle fibres, natural titin has a unique combination of and transition between resilient and energy damping states making it uniquely suited for the crucial biological functions of skeletal and cardiac muscle. Here, the synthetic titin recapitulated these properties, again exceeding the measurements found in natural titin or in myofibrils.

Conclusions and future applications

The team here have harnessed the biosynthetic power of microbes, to produce a novel high-performance material that recaptures the mechanical properties of natural muscle fibres. With high damping capacity, rapid mechanical recovery, in addition to high strength and toughness, it exceeds the performance of many man-made and natural high-performance fibres.

This is the first example of an engineered macroscale material produced from titin, and is done so in a sustainable production process, that is scalable, and biodegradable, making it an excellent candidate for environmentally friendly applications. The team will be looking to use the synthetic material for a wide range of applications from biomedicine such as sutures or tissue engineering to commercial textiles.

They envisage this platform will signify a great expansion of the range of products that will be accessible through engineered microbial synthesis, moving from primarily small molecules, peptides, therapeutic proteins, and industrial enzymes toward effective direct production of high-performance materials.

As the biosynthetic strategy developed here can be applied to other proteins with robust folding properties it offers the chance to produce a new generation of high-performance materials with an expanded range of properties, and will provide an growing variety of sustainable alternatives to traditional petroleum-based polymers. Indeed, a patent has been filed based on the research.

Tissue engineering is a multidisciplined field, which is currently exploiting novel technologies to yield tissue replacement parts and whole organs. Advances in biomaterials and bioengineering have been crucial in the fabrication of tissue, with the aim of mimicking the natural properties of the tissue. Furthermore, ground breaking advancements in 3D bioprinting such as the ability to bioprint blood vessels, and complex biological tissue using seal-healing gels means the technology is moving quickly and starting to live up to the promise. Now, the ability to produce synthetic biomimetic muscle will likely be a much anticipated addition to the tissue engineering tool box.

For more information please see the press release at Washington University in St. Louis

Bowen, C.H., Sargent, C.J., Wang, A., Zhu, Y., Chang, X., Li, J., Mu, X., Galazka, J.M., Jun, Y.-S., Keten, S., et al. (2021). Microbial production of megadalton titin yields fibers with advantageous mechanical properties. Nature Communications 12, 5182.

https://doi.org/10.1038/s41467-021-25360-6